TOSEVEN DM01 Mid Drive Conversion Kit

FREE shipping in USA and Canada for orders over $500

Pairs well with

Product Description

Golden Motor TOSEVEN DM01 Mid Drive Conversion Kit delivers seamless power for bikes, ensuring performance, robust durability, and an exceptional riding experience.

1000w, 68-73mm bottom bracket compatible, 46T chaining, DM01 E-bike Mid-Drive Motor:

Equipped with Torque Sensor & Cadence Sensor.

Up to 1000W Rated Power Output.

Output Torque of 160Nm.

Compatible With 48, 52, 60 Volts Battery Range.

Motor kits include:

46T chainring

Wiring harness

Crank arms with bolts

USB programming cable set

Installation wrench

Thumb throttle

Speed sensor

Anderson power connector

Lights wire connector

Hardware packet.

ENHANCED PERFORMANCE

Better heat dissipation ensures cooler and longer operation, optimizing E-bike motor efficiency.

Enhanced power output ranging from 750W to 1000W for dynamic e-bike performance.

High gear ratio (40.27) provides swift starts and impressive climbs.

Dual-clutch mechanism offers minimal resistance when pedaling E-bike mid-drive motors.

INTEGRATION AND DESIGN

Seamless integration with 95% of standard bike frames for easy installation of E-bike mid-drive motors.

Engineered for a smooth, comfortable journey, resembling the traditional bicycle feel.

Crafted from robust aluminum alloys, ensuring durability in various environments.

Trusted by top electric bicycle manufacturers for enduring performance.

Elevate Your E-bike Journey Today !

Attention: To ensure optimal functioning and longevity, we highly recommend using the motor within the prescribed voltage range. Any unauthorized alterations beyond this range may void the warranty coverage.

https://www.youtube.com/watch?v=wqeIO3oGB8I

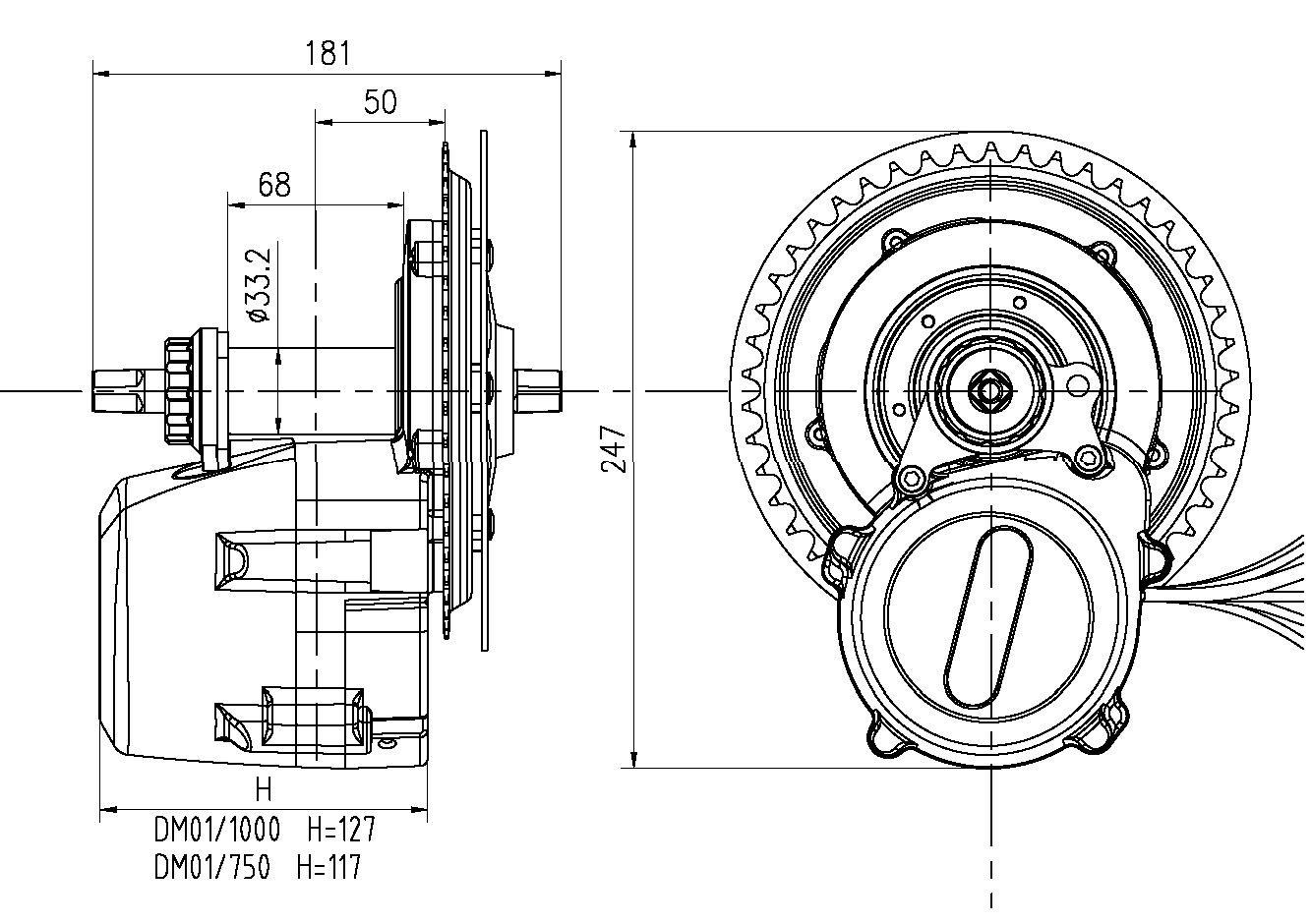

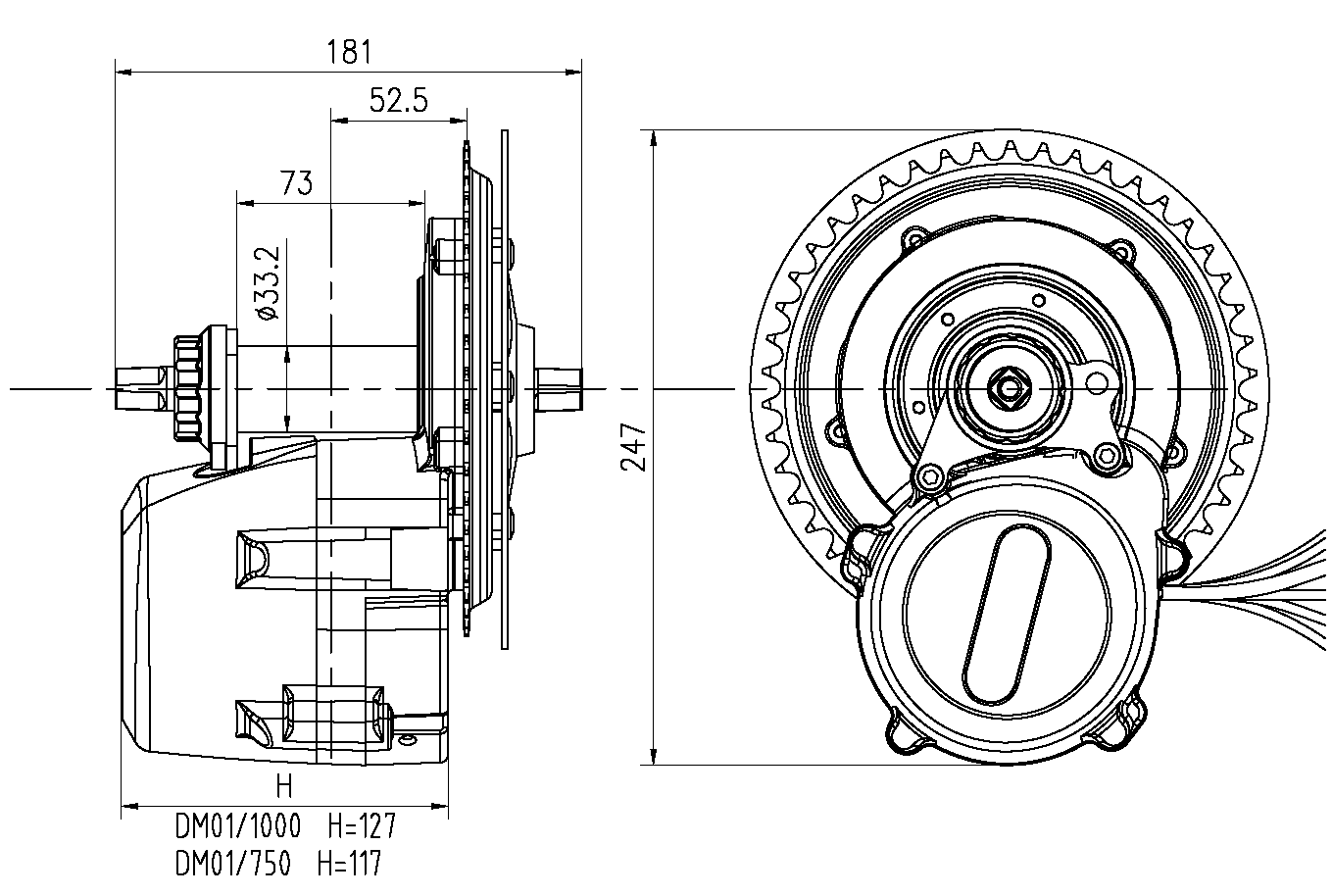

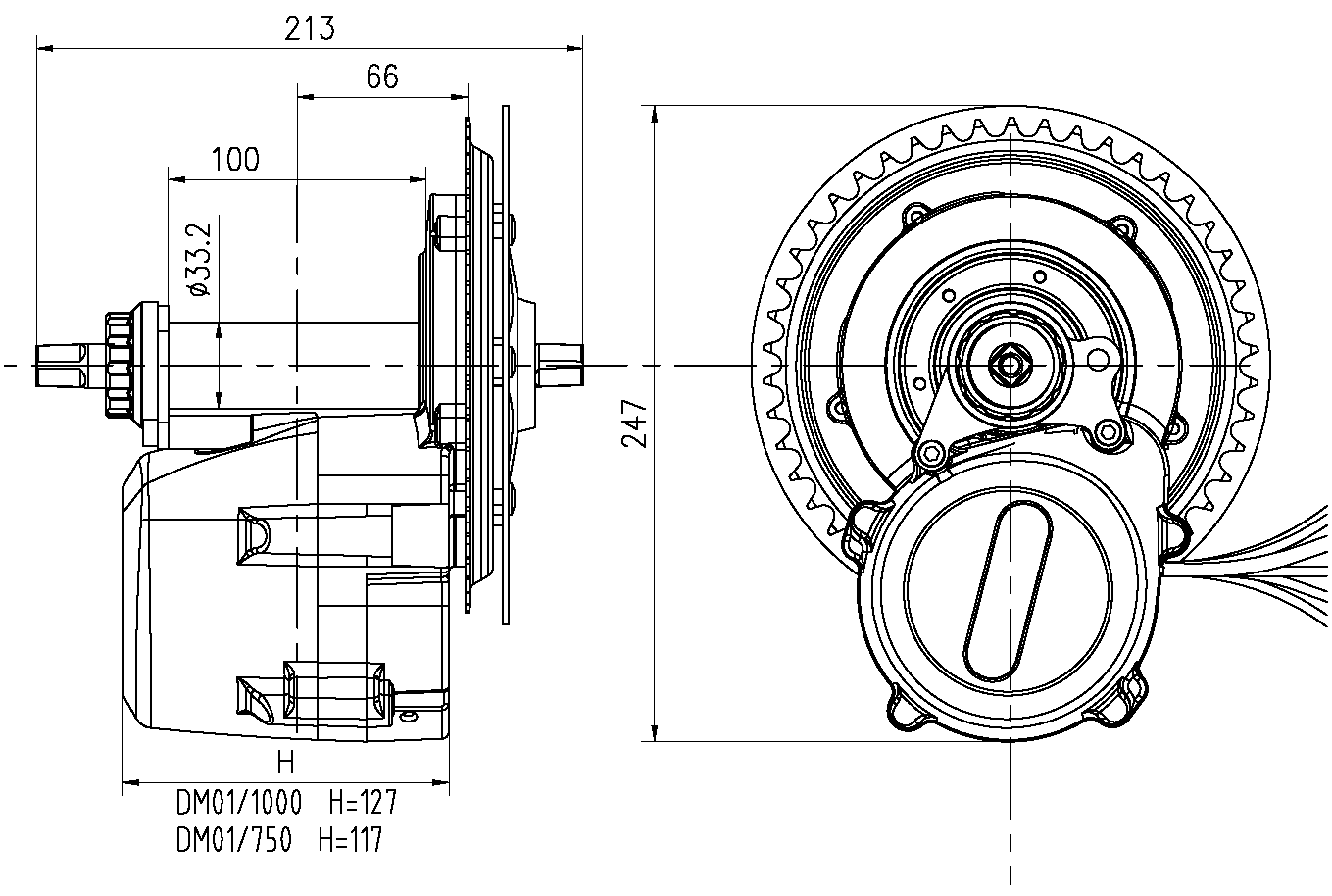

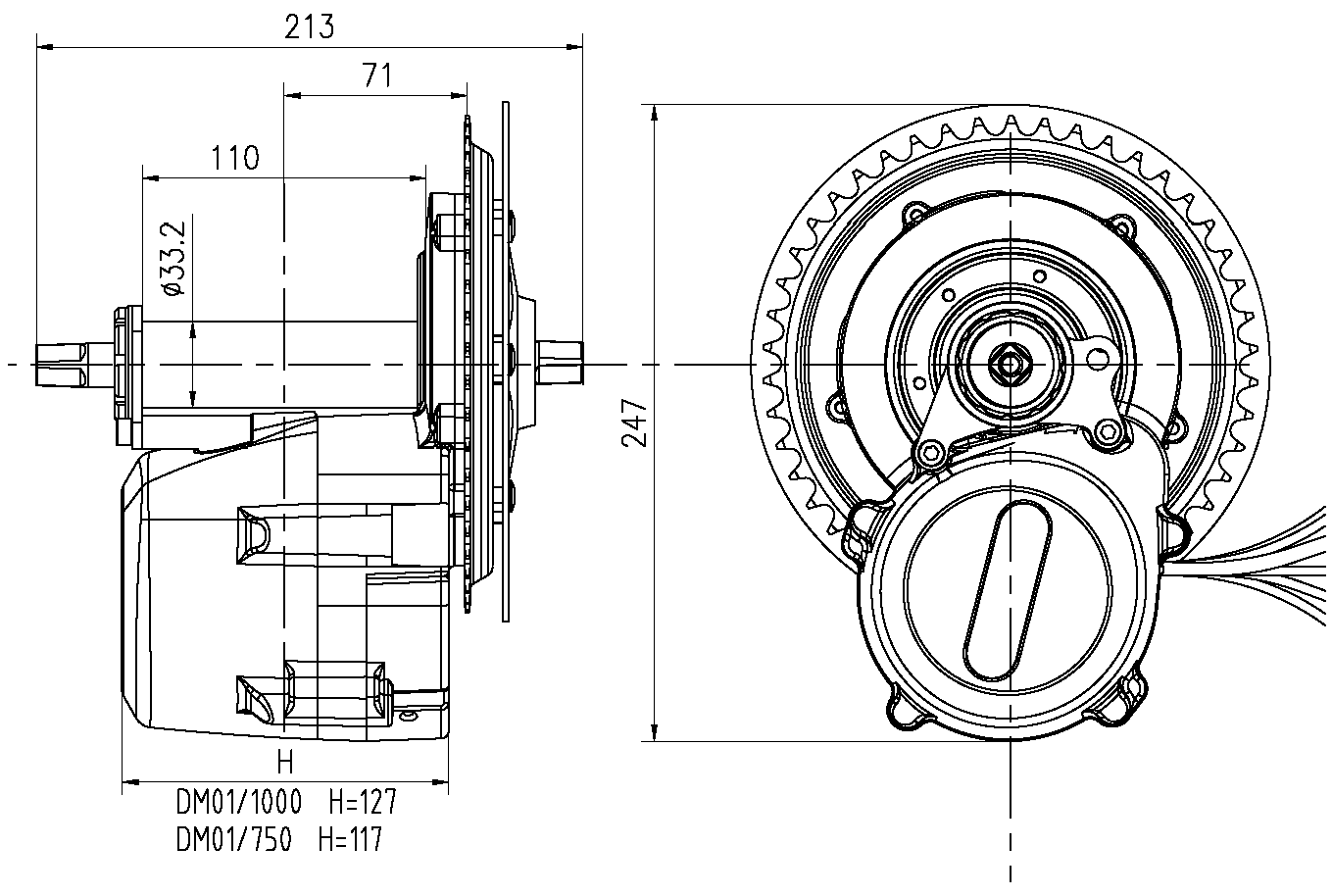

Dimensions

① BB=68 CL=50 (or 59)

Model: DM01-1000 DM01-750

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

Installation

Installation

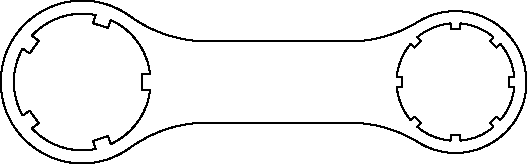

1) Installation Tool

① Special wrench:

② General tools: 6mm Allen wrench

8mm Allen wrench

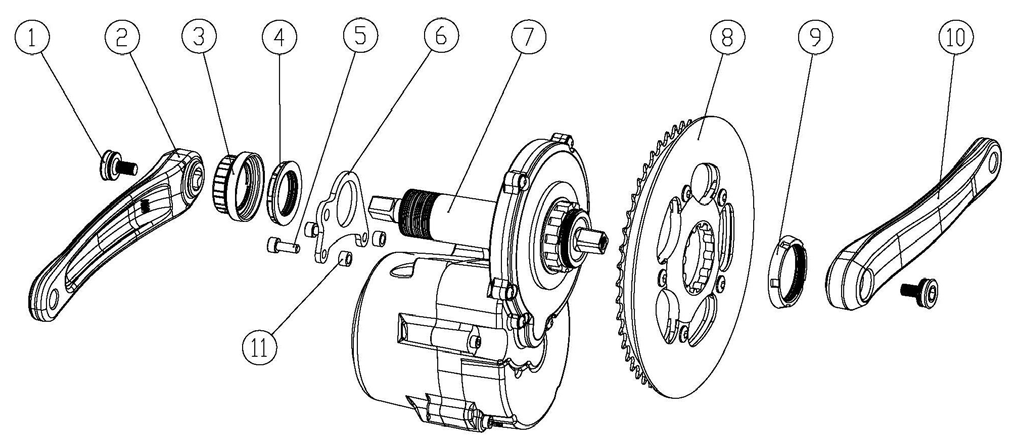

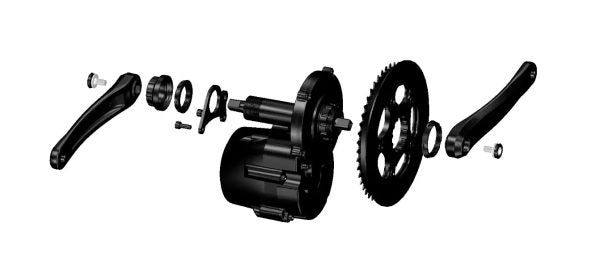

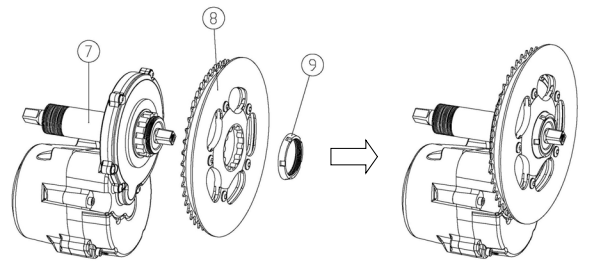

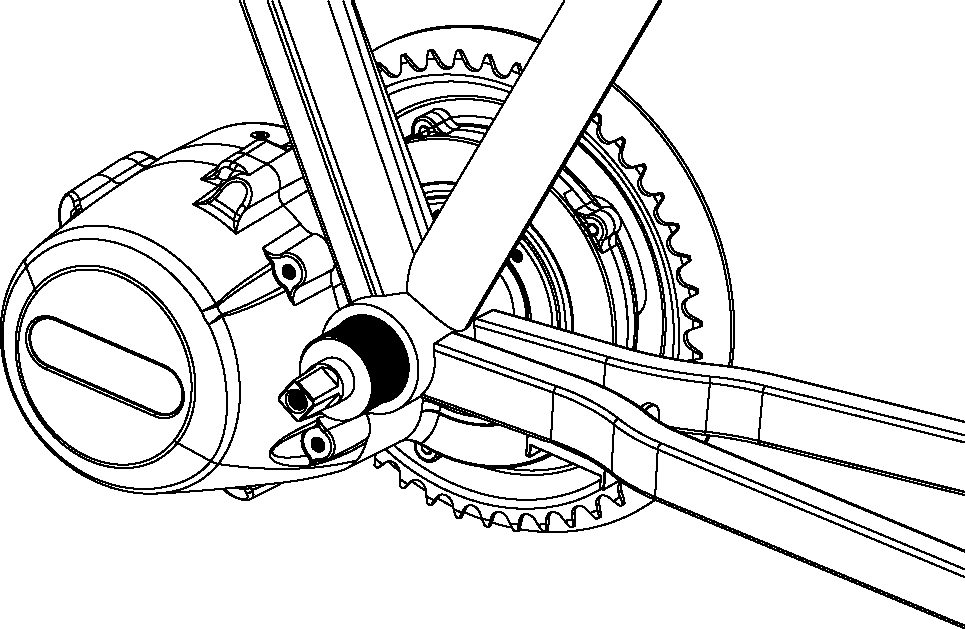

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

② General tools: 6mm Allen wrench

8mm Allen wrench

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

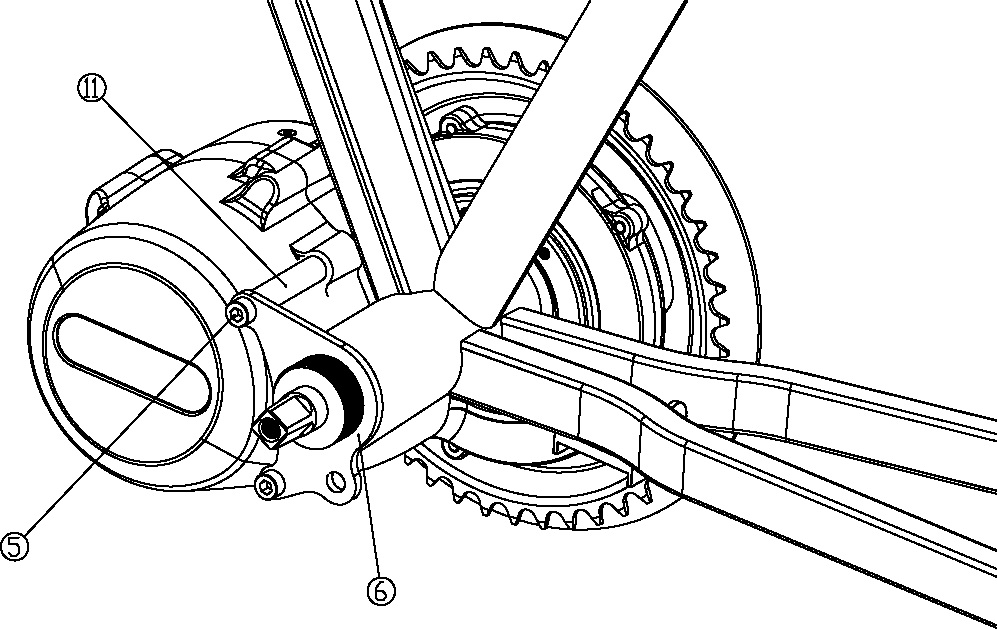

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

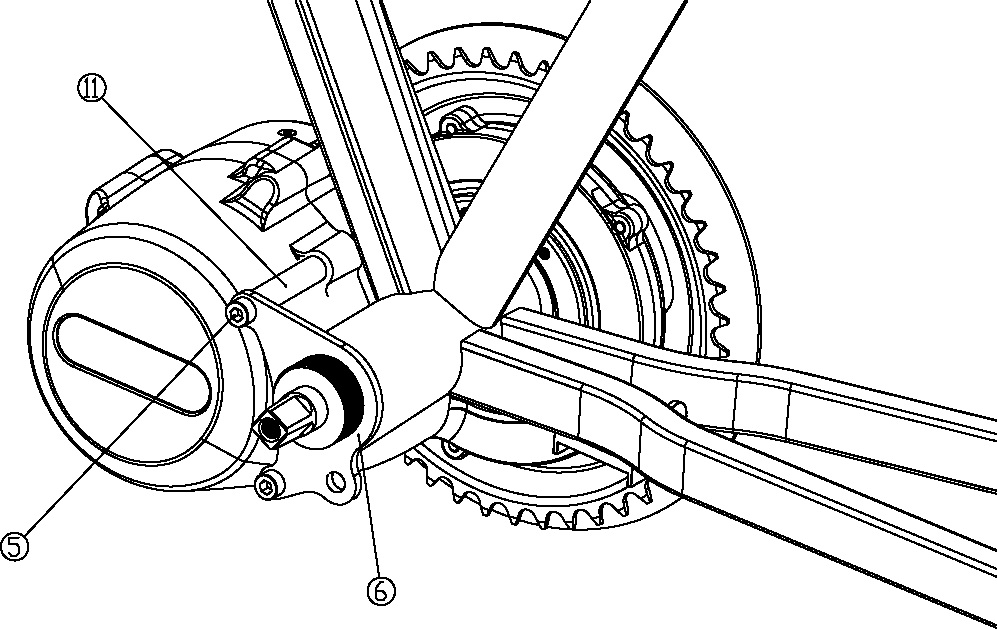

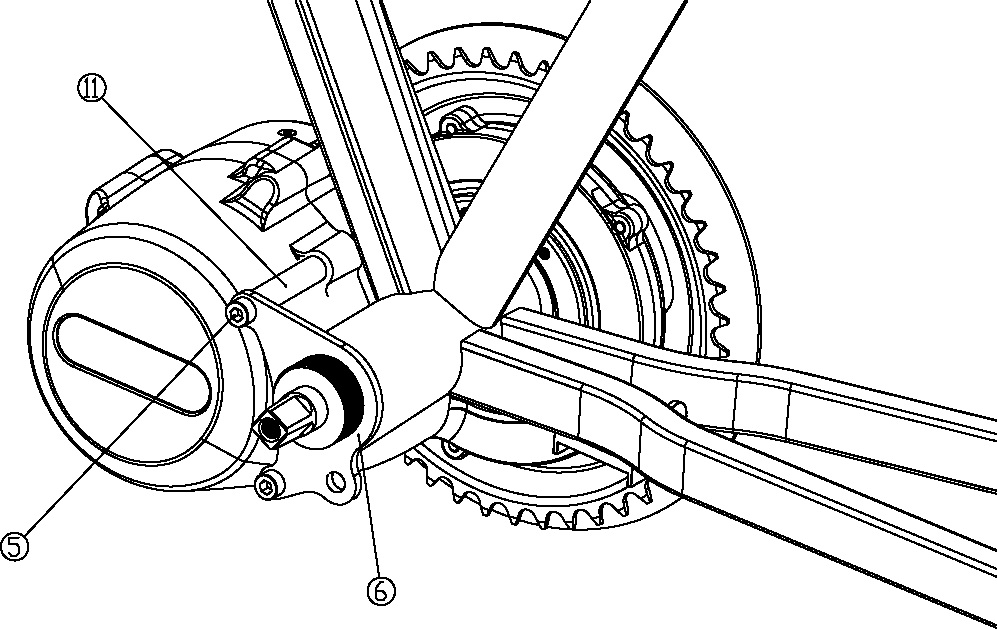

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

- BB=73

- BB=73

- BB=100~110

- BB=100~110

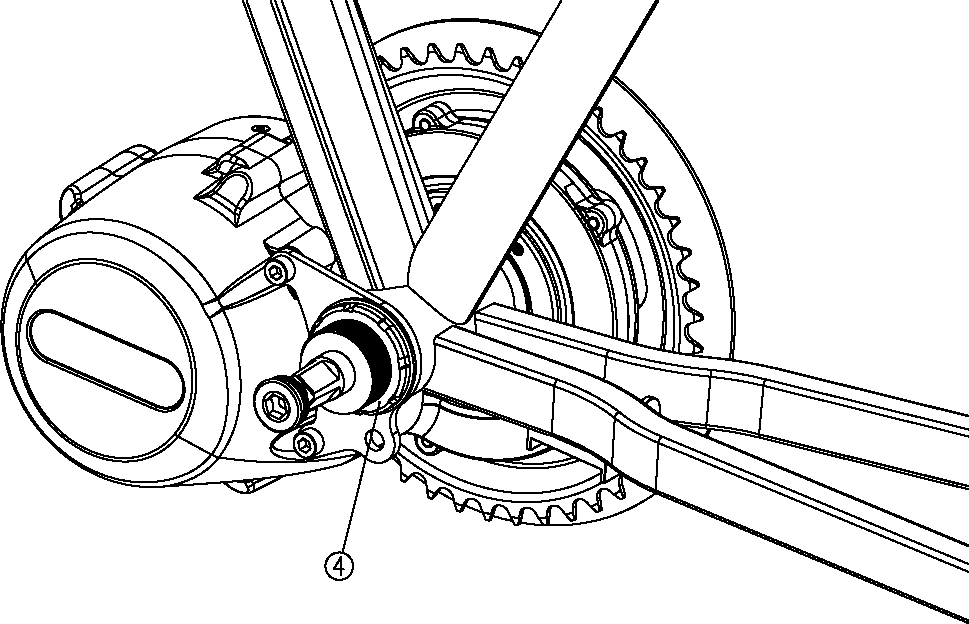

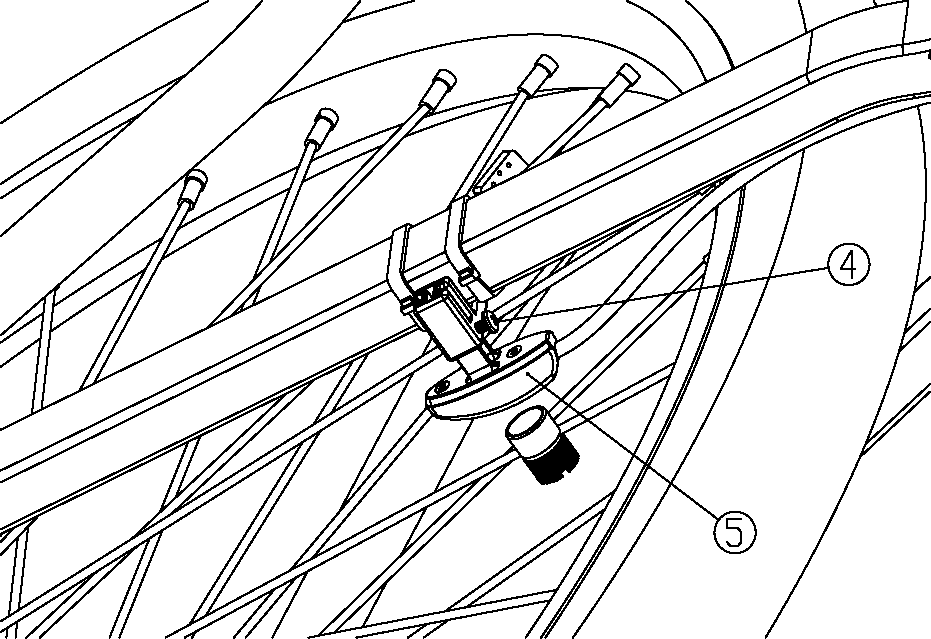

③ Non-standard nuts installation

-Tools: Special wrench

-Components(see: factory configuration):non-standard nut 4

-Requirement: before tightening the nut, turn the motor clockwise until the

motor is close to the lower tube of the frame and does not turn until it

stops, then use a special wrench to tighten the nut, torque is 45-50Nm when

tightening

-Diagram:

③ Non-standard nuts installation

-Tools: Special wrench

-Components(see: factory configuration):non-standard nut 4

-Requirement: before tightening the nut, turn the motor clockwise until the

motor is close to the lower tube of the frame and does not turn until it

stops, then use a special wrench to tighten the nut, torque is 45-50Nm when

tightening

-Diagram:

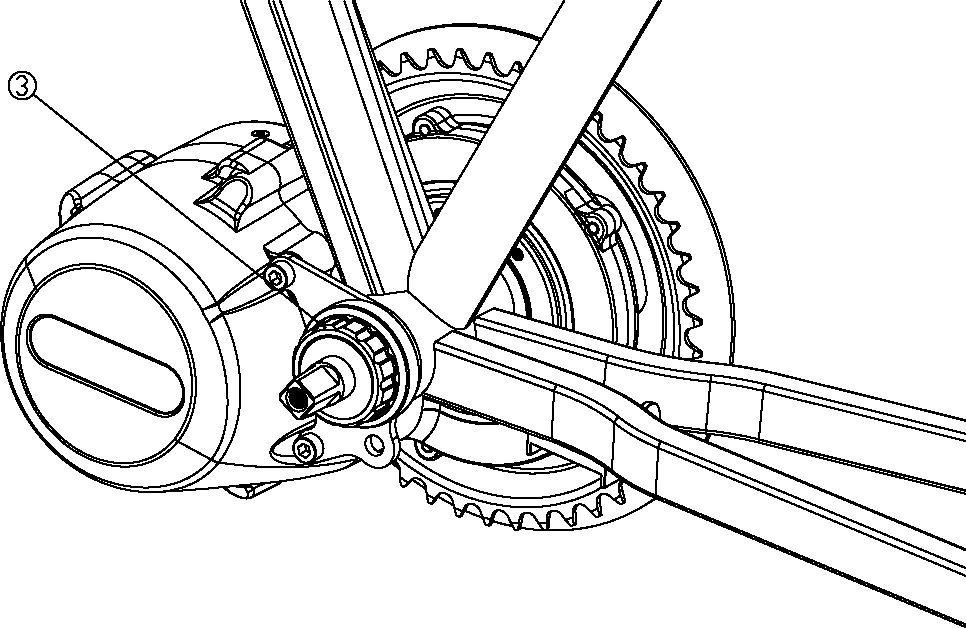

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

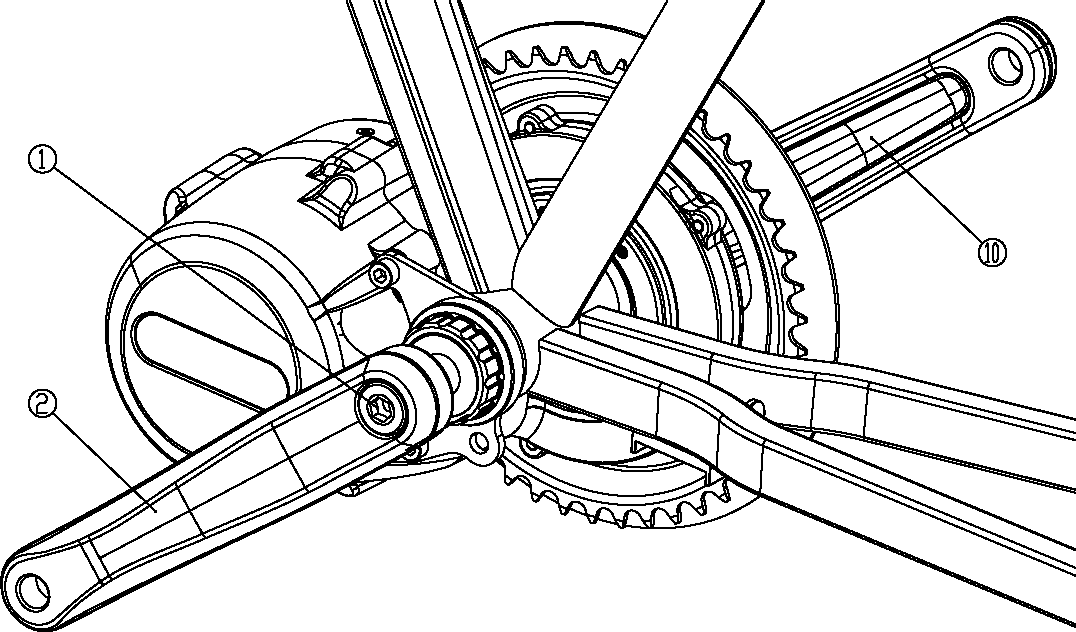

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

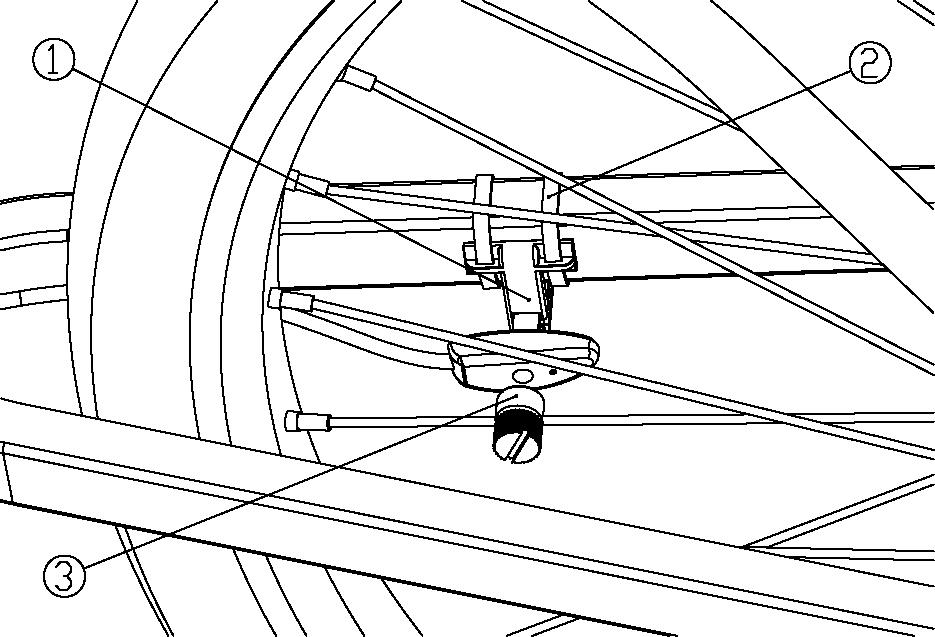

4) Speed Sensor Installation

① Fasten the sensor to the frame flat fork with 2 cable ties, then install the

magnets on the wheel spokes with a flat-blade screwdriver

Notice:Make sure the magnetic field side of the magnet is aligned with the

circular mark on the sensor

② Loosen the screws on the sensor with a Phillips screwdriver, then move the

receiver of the speed sensor, to ensure that the distance between the circular

marking to the sensor surface and the magnet is from 2 to 10 mm, the tighten

the screw with a screwdriver to complete the installation

4) Speed Sensor Installation

① Fasten the sensor to the frame flat fork with 2 cable ties, then install the

magnets on the wheel spokes with a flat-blade screwdriver

Notice:Make sure the magnetic field side of the magnet is aligned with the

circular mark on the sensor

② Loosen the screws on the sensor with a Phillips screwdriver, then move the

receiver of the speed sensor, to ensure that the distance between the circular

marking to the sensor surface and the magnet is from 2 to 10 mm, the tighten

the screw with a screwdriver to complete the installation

1-Sensor 2-Tie 3-Magnet 4-Screw 5-Receiver

5) Wiring

① Operation:

Insert the plugs on the bus cable, battery and speed sensor to the

corresponding plugs of the motor,the other end of the bus cable can be plugged

into the display, brake, throttle, etc.

② Precautions:

Try not to pass all cables through the narrow space of the motor and bike

frame, so as to avoid the cables being squeezed and damage

5. Warranty: The warranty on the motor is valid for 12 months from the SN date of

production. This warranty does not mean that seller's products are not free from

damage or permanent use.

6. Compatibility: Due to different communication protocols, our motors can only be

used with the accompanying accessories we provide and are not compatible with

accessories from other brands.

ATTENTION: WARRANTY VOID IF SEAL IS REMOVED

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

Contact Us

Use this text to answer questions in as much detail as possible for your customers.